Series 4600

Lever Switch

Lever Switch

Railroad Control Equipment

HOME |

CONTROL PANELS |

SWITCHES |

CONTROL UNITS

Home

Products

Contact Us

Contact Us

Home

Home

Home

Products

Products

Projects

Projects

Projects

Contact Us

Products

Projects

Contact Us

SUPPORT EQUIPMENT |

CUSTOM SPECIAL PARTS |

CONTACT ENTECH

Home » Control Consoles/Panels » Grid & Tile Mosaic

» Grid & Tile Mosaic

» Metallic Face Panels and Consoles

» Rack Mounted Panels

» Product Images

» PDF Datasheet

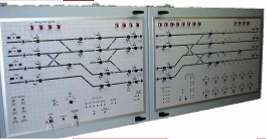

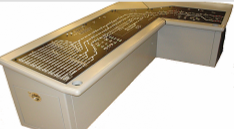

Grid & Tile Mosaic

This 24 mm system is the latest generation "intelligent" mosaic mimic system and is the product of over 30 years of continuous development. The modular graphic display or control fascia is tailored to the clients' application needs and it can provide everything from a standard 19" rack fascia, operator control console or desk/control panel section, to a complete free standing display/control center for an entire control room wall.

Modern mosaic panels still provide the best cost effective solution for many 24/7 process control and graphic display applications. They are a well proven, secure and robust engineered control solution giving total confidence to Plant and Control Room operators in safety critical environments. These systems require minimal routine maintenance or disruption to active (online) operation. An additional benefit is very low lifetime ownership costs.

This 24 mm system is the latest generation "intelligent" mosaic mimic system and is the product of over 30 years of continuous development. The modular graphic display or control fascia is tailored to the clients' application needs and it can provide everything from a standard 19" rack fascia, operator control console or desk/control panel section, to a complete free standing display/control center for an entire control room wall.

Modern mosaic panels still provide the best cost effective solution for many 24/7 process control and graphic display applications. They are a well proven, secure and robust engineered control solution giving total confidence to Plant and Control Room operators in safety critical environments. These systems require minimal routine maintenance or disruption to active (online) operation. An additional benefit is very low lifetime ownership costs.

Railroad Control Equipment

Custom Switches

Ground Detector Equipment

Control Consoles/Panels

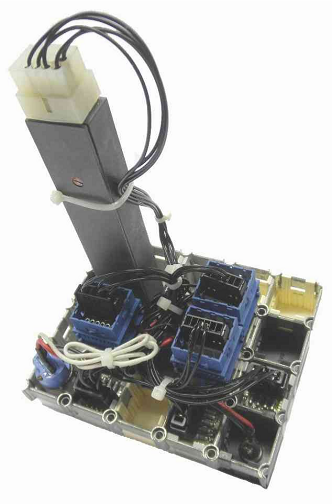

The system provides LED or specialty meter indication, switch/pushbutton modules, and can interface with a variety of I/O modules, connection plugs and sockets.

The key benefit of this type of system is the ease of adaptation for future modifications. Devices may be added or removed to the demands of the user, with the mosaic always maintaining a high quality appearance without showing a visible history of the modifications. Circuit or graphic changes look like an original initial construction.

The key benefit of this type of system is the ease of adaptation for future modifications. Devices may be added or removed to the demands of the user, with the mosaic always maintaining a high quality appearance without showing a visible history of the modifications. Circuit or graphic changes look like an original initial construction.

Controller Switches

Rack Mounted Panels

The Tiled Fascia

The tiles are molded from Makrolon polycarbonate and have the following characteristics:

The tiles are molded from Makrolon polycarbonate and have the following characteristics:

- a non-reflective surface

- non-flammable/self extinguishing

- anti-static material

- non-toxic and halogen free (*)

- RAL 7035 light grey

- RAL 6019 light pale green

- RAL 7016 anthracite

- RAL 1015 beige

- opal translucent white (for rear illumination of full tile area)

The tile is not a 'plate', but has a body depth of 15mm (.59"). This is important for the control and indication features of the system, and also provides for the flush mounting of instruments and meters with bevels of up to 15mm (.59") deep. This helps to insure the graphic display does not become visually dominated by the presence of the instruments.

In addition to the basic 24mm (.94") square tile, the system offers tiles 48mm (1.89") square and 48mm x 24mm, plain or simulated. Simulated tiles are molded to give the appearance of a multiple of 24mm square tiles and may be used, for instance, where large barrel switches of industrial pattern pushbuttons need to be accommodated. For special tiles, where plenty of functionality like pushbuttons and LEDs have to be accommodated in a restricted space, the Subklew SMF48x24 and SMF48x48 Functional Tile System is available.

No special mounting tiles or frames are necessary when mounting normal DIN standard instruments. A range of instruments for analog or industrial protocol input are easily mounted without any cut out in the grid.

Tiles are removable from the front without any need for rear access by using a simple extraction tool, which causes no damage to the tile or features engraved and painted on the tile.

No gaps are visible between adjacent tiles, or tiles and the outer aluminum frame.

(*) The Makrolon-type 6560 is supplied with minor quantities of ingredients for fire protection and have a 94V0 UL flame rating.

Accessory Control Panels

Custom Consoles

Part Manufacturing

Support Equipment

Control Units

Entech Controls Corporation | 8 Tower Circle West | Ormond Beach, FL 32174

Tel: (386) 672-7335 | Fax: (386) 672-7233

Tel: (386) 672-7335 | Fax: (386) 672-7233

Entech Controls Corporation | 8 Tower Circle West | Ormond Beach, FL 32174

Tel: (386) 672-7335 | Fax: (386) 672-7233

Tel: (386) 672-7335 | Fax: (386) 672-7233

Mosaic Assemblies

The basic construction of the tile support matrix comprises the assembly of precision die-cast alloy grids within an aluminum extruded bezel section which provides great strength and enables easy mounting of a variety of panel sizes.

Mosaic assemblies of any size may be constructed either within the constraints of any handling limitations, or as sub-sections which, when mounted within an opening, may be joined to provide an overall tiled surface which is flat with invisible joints between the tiles on either side of a joint line.

The grid is manufactured as a 24 x 12 tiles matrix (576mm x 288mm or 22.68" x 11.34"), and the design is such that it may be cut and joined to an adjacent casting at any 24mm (.94")grid intersection. Flat surface alignment of tiles is ensured within a tolerance of less than 0.1mm (.004") in height, and without imposing any limitation on the positioning of control and indication devices or instrumentation.

The grid may be cut at any point to provide an aperture for the mounting of DIN or non-DIN instruments without any significant reduction to the overall structural integrity. Openings within the grid may be closed by inserting and fixing an 'infill' grid section without compromising the appearance or strength of the area. The positioning of any control or indication devices is not affected and no special tools or jigs are necessary to install or uninstall a particular device.

Where necessary, the replacement of a complete grid casting is possible from the front of the display, although font and rear access is advisable to make clean alterations.

The display matrix assembly is general framed within a silver anodized aluminum bezel extrusion, however, it may be finished (on request) to any specified color. Alternatively steel, stainless steel or hardwood trims may also be specified as special order items.

The basic construction of the tile support matrix comprises the assembly of precision die-cast alloy grids within an aluminum extruded bezel section which provides great strength and enables easy mounting of a variety of panel sizes.

Mosaic assemblies of any size may be constructed either within the constraints of any handling limitations, or as sub-sections which, when mounted within an opening, may be joined to provide an overall tiled surface which is flat with invisible joints between the tiles on either side of a joint line.

The grid is manufactured as a 24 x 12 tiles matrix (576mm x 288mm or 22.68" x 11.34"), and the design is such that it may be cut and joined to an adjacent casting at any 24mm (.94")grid intersection. Flat surface alignment of tiles is ensured within a tolerance of less than 0.1mm (.004") in height, and without imposing any limitation on the positioning of control and indication devices or instrumentation.

The grid may be cut at any point to provide an aperture for the mounting of DIN or non-DIN instruments without any significant reduction to the overall structural integrity. Openings within the grid may be closed by inserting and fixing an 'infill' grid section without compromising the appearance or strength of the area. The positioning of any control or indication devices is not affected and no special tools or jigs are necessary to install or uninstall a particular device.

Where necessary, the replacement of a complete grid casting is possible from the front of the display, although font and rear access is advisable to make clean alterations.

The display matrix assembly is general framed within a silver anodized aluminum bezel extrusion, however, it may be finished (on request) to any specified color. Alternatively steel, stainless steel or hardwood trims may also be specified as special order items.

Entech Controls Corporation | 8 Tower Circle West | Ormond Beach, FL 32174

Tel: (386) 672-7335 | Fax: (386) 672-7233 | entechsales@cfl.rr.com

Tel: (386) 672-7335 | Fax: (386) 672-7233 | entechsales@cfl.rr.com

The bezel section accepts a range of mounting clamps designed for the fixing of mosaic assemblies of various sizes within enclosure opening. The rear of the matrix provides for special aluminum extruded rails running vertically or horizontally at regular intervals. These are secured to the bezel and grid to ensure a strong and rigid overall assembly.

These extruded sections are designed to accept a range of captive nuts at any position within their length in each of four places, to facilitate the mounting of terminal rails, instrument support rails, cable trunking, etc.

Where necessary, a mosaic structure can be assembled without a bezel or with a special bezel to suit a specific application - i.e., when mounted directly into a wall aperture, a special wide bezel section is available which would cloak any variance on the sub-frame opening.

The final assembly is structurally self-supporting without reliance on its enclosure for strength or support. In addition it can be capable of supporting large case instruments and ever Rear Projection Units for combining dynamic information with the mimic.

Entech engineering can work with the customer to design and build the project to the allowable space for each custom application. Detailed drawings are provided to insure easy long term serviceability. Contact the factory for application assistance.

These extruded sections are designed to accept a range of captive nuts at any position within their length in each of four places, to facilitate the mounting of terminal rails, instrument support rails, cable trunking, etc.

Where necessary, a mosaic structure can be assembled without a bezel or with a special bezel to suit a specific application - i.e., when mounted directly into a wall aperture, a special wide bezel section is available which would cloak any variance on the sub-frame opening.

The final assembly is structurally self-supporting without reliance on its enclosure for strength or support. In addition it can be capable of supporting large case instruments and ever Rear Projection Units for combining dynamic information with the mimic.

Entech engineering can work with the customer to design and build the project to the allowable space for each custom application. Detailed drawings are provided to insure easy long term serviceability. Contact the factory for application assistance.

Entech Controls Corporation 8 Tower Circle West Ormond Beach, FL 32174

Tel: (386) 672-7335 Fax: (386) 672-7233 entechsales@cfl.rr.com

Tel: (386) 672-7335 Fax: (386) 672-7233 entechsales@cfl.rr.com

Last Revised February 14, 2012

2013 Entech Controls Corporation